Right-On FiberFlex® Commercial Flooring

What is Right-On FiberFlex Commercial Flooring®

Right-On FiberFlex® is a tough and substantial commercial flooring product engineered to endure the harshest environments and a superior alternative to the limitations of epoxy flooring.

This durable flooring is specifically designed to be installed in locations that demand resistance to chemicals, microbes, water, abrasion, impact, thermal (hot or cold) and other real-world challenges and has a 20 Year Warranty giving you peace of mind for years to come.

Right-On FiberFlex Benefits

Long Lasting

Slip Resistant

Environment Friendly

Microbial Resistant

Easy to Maintain

Chemical Resistant

Where should Right-On FiberFlex® Flooring be Installed?

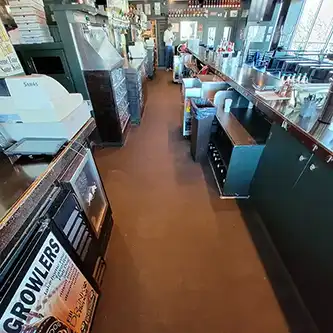

Right-On FiberFlex® flooring is a clean, durable wear, slip resistant layer that is ideal to be installed in commercial environments where vinyl, tile, laminate, epoxy, or other flooring options fail to have longevity:

- Commercial Kitchens

- Walk-In Coolers

- Parking Garages

- Medical Facilities

- Veterinary Clinics

- Locker Rooms

- Weight Rooms

- Laboratories

- Entrance Ways

- Balconies

- Factory and Plant Floors

- Clean Rooms

- Hospitals

- Nursing Homes

- Server Rooms

- NOC Centers

Right-On FiberFlex® Lasts Longer

Right-On FiberFlex® is 20 times stronger than epoxy, won’t crack like tile, and is more durable and chemical resistant than painted surfaces or laminates and is backed by a 20 Year Manufacturers Warranty. Contact your Right-On FiberFlex® representative for details.

Water Resistant – Non-porous flooring surface creates a water resistant membrane.

Weather Impacted – Water and thermal resistant material is designed for decks and balconies.

Non-Skid/Slip Resistant – Excellent for commercial kitchens, laundry rooms or wherever moisture may be present.

Impact/Abrasion Resistant – Designed to resist scratching and chipping from tools, furniture, appliances and the day to day abuse in a busy commercial kitchen or factory.

Chemical Resistant – Right-On FiberFlex® has been tested and shows no visible change with exposed to common commercial chemicals like automotive oil, Diesel fuel, Ethylene Glycol and many more (see below).

| SPECIMEN ID | CHEMICAL | VISUAL EVALUATION |

|---|---|---|

| Right-On FiberFlex | Automotive Oil | No visual change |

| Right-On FiberFlex | Diesel | No visual change |

| Right-On FiberFlex | Ethylene Glycol | No visual change |

| Right-On FiberFlex | Gasoline, Unleaded | No visual change |

| Right-On FiberFlex | Hydraulic Oil | No visual change |

| Right-On FiberFlex | Hydrochloric Acid, 25% | No visual change |

| Right-On FiberFlex | Hydrogen Peroxide, 10% | No visual change |

| Right-On FiberFlex | Kerosene | No visual change |

| Right-On FiberFlex | Mineral Spirits | No visual change |

| Right-On FiberFlex | Phosphoric Acid, 5% | No visual change |

| Right-On FiberFlex | Potassium Hydroxide, 20% | No visual change |

| Right-On FiberFlex | Potassium Hydroxide, 50% | No visual change |

| Right-On FiberFlex | Sodium Hydroxide, 20% | No visual change |

| Right-On FiberFlex | Sulfuric Acid, 10% | No visual change |

Bacteria, Fungus and Microbe Resistant – No growth detected after 14 days of testing (Rating of 0) – (Test: MIL-STD-810 G1 508.7)

Durable – Right-On FiberFlex® flooring eliminates problems such as chipping, peeling, cracking, bubbling, cracked tiles, gapping seams and many other issues commonly faced with flooring installations. As you can see from the results below, durability testing on Right-On FiberFlex® for Hardness, Tensile, Elongation and Impact Resistance yielded the following results:

| TEST NAME | TEST METHOD | VALUE |

|---|---|---|

| Hardness | ASTM D-2240 | 80 ± 5 shore A |

| Tensile | ASTM D-412 | 2000 ± 700 psi |

| Elongation | ASTM D-412 | 350 ± 50 |

| Impact Resistance | ASTM G14 | > 200 lbs. |

Installation and Maintenance

Fast & Easy to Install – Right-On FiberFlex is manufactured in 7’x25′ & 12’x25’ rolls, installs like vinyl flooring and requires no special equipment.

Fast application – Pre engineered rolls come in assorted colors that are ready for foot traffic within 4 hours and full service traffic within 24 hours.

Adhesive – When installed with the manufacturer approved adhesive, Right-On FiberFlex can be ready for traffic within hours with no harmful VOC’s emitted.

Save Money – The cost of prep and clean up is reduced due to pre-engineered rolls and you can return to service within 24 hours; plus Right-On FiberFlex® never needs to be repainted providing long term savings on both labor and materials.

Easy To Clean And Maintain – Right-On FiberFlex® is strong and easy to clean without the need for custom cleaners or chemicals and can be cleaned with a wide range of standard and green cleaning materials designed for commercial kitchens, nursing homes, laboratories, healthcare and medical facilities.

Low VOC’s – Right On FiberFlex® emits Low VOC’s (Volatile Organic Compounds) and conforms to CDPHv1.2 standard so it qualifies for LEED credits.

Premade rolls are portable and can be stored and installed as needed

20 Year Warranty

Right On FiberFlex® Flooring Roll Specifications:

Size: 7’x25′ & 12’x25’ rolls

Temperature Range: -40°F – 160°F

Surface Finish: Slip-resistant (even when wet).

Storage: Rolls can be stored and installed as needed.

Warranty: 20 Years (contact us for details).

Color Options: Black, Dark Blue, Graphite, Medium Gray, Tan, Safety Yellow, Safety White, Safety Red, Safety Green, and Custom Colors Available.

Manufacturing: Proudly made in the USA.

Safety Striping & Safety Flooring Now Available

Right-On FiberFlex Safety Striping is now available in:

Right-On FiberFlex Safety Striping is now available in:

*Peel-and-stick or glue-down, depending on traffic patterns.

*Standard 4” wide x 50’ long. (2 “-6” widths available)

Colors: Yellow, Red, Green, White, Custom Colors Available.

Warranty: 5-year manufacturer warranty.

Right-On FiberFlex Safety Flooring is now available and is perfect for walkways, ramps, stairways, and entryways.

*Up to 6′ wide, as needed.

Colors: Yellow, Green, Red, White

Warranty: 20-year manufacturer warranty.

Stair treads are coming soon.

Right-On FiberFlex Contractor Pricing

| 300 sq ft rolls (12’x25′) | Retail Cost | Contractor Pricing | Distributor Pricing |

|---|---|---|---|

| Price Per Roll | Contact Us | Contact Us | Contact us. Become a distributor. |

| Adhesive (2 Gallons) | Contact Us | Contact Us | Contact us. Become a distributor. |

| Seam Seal | Contact Us | Contact Us | Contact us. Become a distributor. |

| Total | Contact Us | Contact Us | Contact us. Become a distributor. |